APH HYDROSTATIC VIBRATORY PLATES

Ammann APH Hydrostatic Vibratory Plates deliver compaction power and productivity to jobsites. The plates have exceptional drive and climbing power, even when working in cohesive soils.

The compactors enable smooth directional changes and easy operation, even by the inexperienced. Operators can adjust to jobsite conditions by simply regulating the engine revolutions.

Ready to learn more? Click on the product hotspots or the chat contact.

APH HYDROSTATIC VIBRATORY PLATES

Superior compaction performance

These plates are at their best when productivity matters most, regardless of the application. The powerful vibratory system delivers strong compaction forces and fast working speeds. The machines can compact large areas in the same amount of time as some double-drum rollers. The plates’ unmatched manoeuvrability enables access to confined areas that a heavier roller could never reach.

Intelligent compaction for maximum performance

Ammann Compaction Expert (ACE) is an automated compaction measurement and control system. It is the same technology that has been used on Ammann heavy compaction machines for years. ACE provides operators with an accurate indication of soil stiffness and whether desired compaction has been achieved. This improves operator output and minimises the time needed to reach compaction goals.

Fully hydraulic drive

The APH plates’ hydraulic drive system provides significantly more force than its conventional counterparts. This makes Ammann APH plates the right choice for those who require a machine that delivers productivity while achieving compaction goals for quality and density.

APH HYDROSTATIC VIBRATORY PLATES

The right fit on your jobsite

The triple-shaft technology and size of the APH plates help them power through varied ground conditions on almost any jobsite. This versatility makes the plates an essential part of any fleet.

Rockfill material

The plates’ high compaction output helps them master surfaces where the highest impact force is required.

Soil and sand

Smooth operation combines with the unique vibratory system to push through wet and saturated ground that can leave lesser plates stuck.

Thick paving stones

Each APH plate can be equipped with an optional paving pad – a rubber mat that quickly attaches beneath the base plate – to protect the stones from being damaged.

APH HYDROSTATIC VIBRATORY PLATES

Precise control

Orbitrol steering

Orbitrol steering controls the adjustment of the centrifugal weights, allowing a smooth change of direction. Machine speed and direction can be adjusted by a simple turn of the drive knob. Orbitrol steering also helps with productivity and safety in corners and other tight spots. The machine also can hover and provide on-the-spot compaction for challenging areas.

APH HYDROSTATIC VIBRATORY PLATES

Safety and protection

Low-vibration guide handle

The standard guide handle for APH plates is isolated to minimise hand-arm vibration. Levels lower than 2.5 m/s2 enable operators to work longer shifts with the best comfort. The vibration levels are so low that safety codes do not require documentation of operator hours.

Safety and control

The guide handle can be folded during operation to help the plates fit into tight spaces. An emergency stop on the handle provides safety. The drive system shuts off immediately if the sensor encounters an object.

Protective frame and covers

A new, updated machine frame offers significant protection, while an additional cover guards the vibratory system.

Secure transport

All APH plates are equipped with lifting and tie-down points that are based on European Rental Association (ERA) guidelines. The tiedown points make securing the machine fast and easy, ensuring success so that risks are minimised. A central lifting hook is integrated into the frame.

APH HYDROSTATIC VIBRATORY PLATES

Serviceability

Protective frame and covers

Key parts and components are protected when things get rough. A new, updated machine frame offers significant protection, while an additional cover guards the vibratory system. Fleet owners and rental companies appreciate this extra protection.

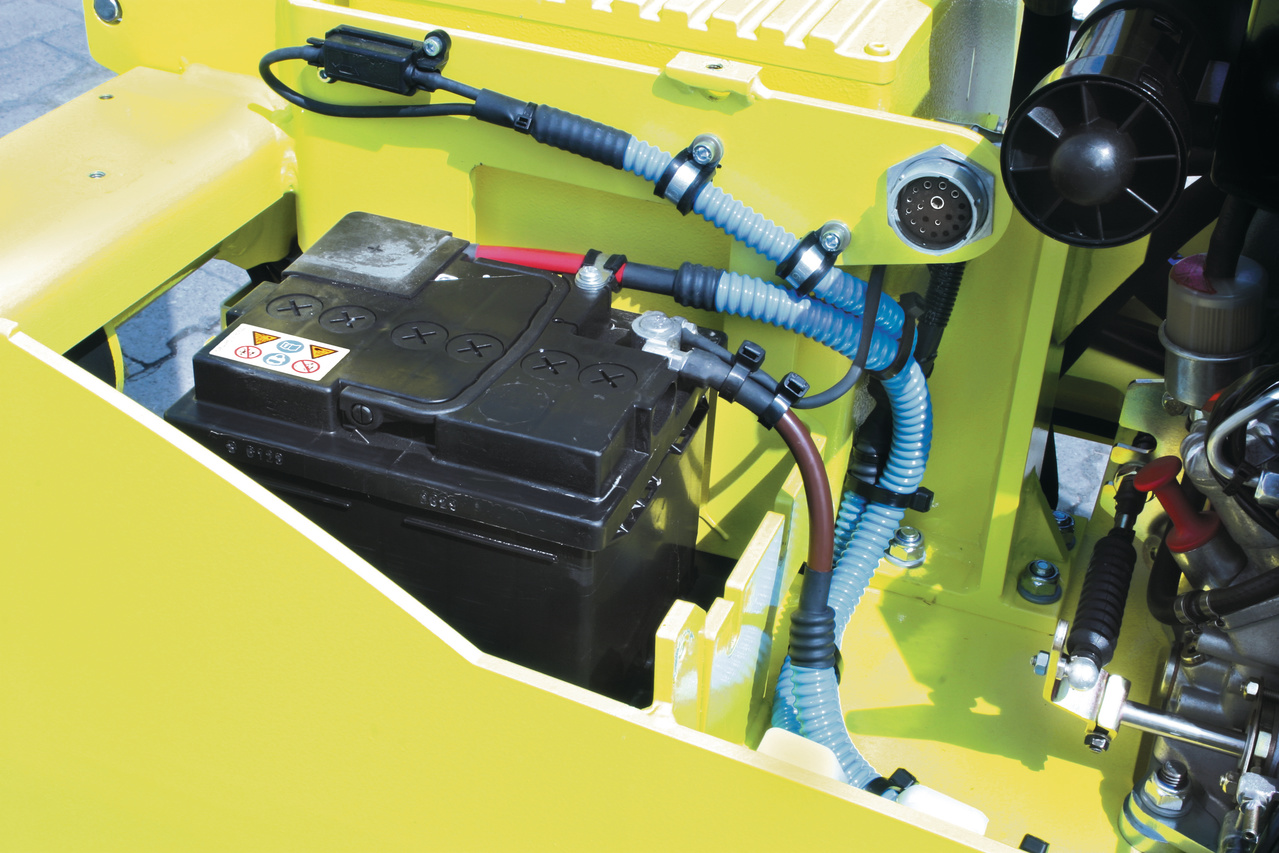

Tool-free daily inspection

Perfect access to all daily inspection points while also offering a quick overview of fluid levels. No tools are required to access daily service points, ensuring the maintenance is completed quickly.

Hydraulic drive

A powerful hydraulic system is built without any mechanical parts such as a centrifugal clutch or V belt. This technical solution reduces wear on the main components, improves productivity and reduces machine downtime. Service intervals are also extended.

APH HYDROSTATIC VIBRATORY PLATES

Productivity at its best

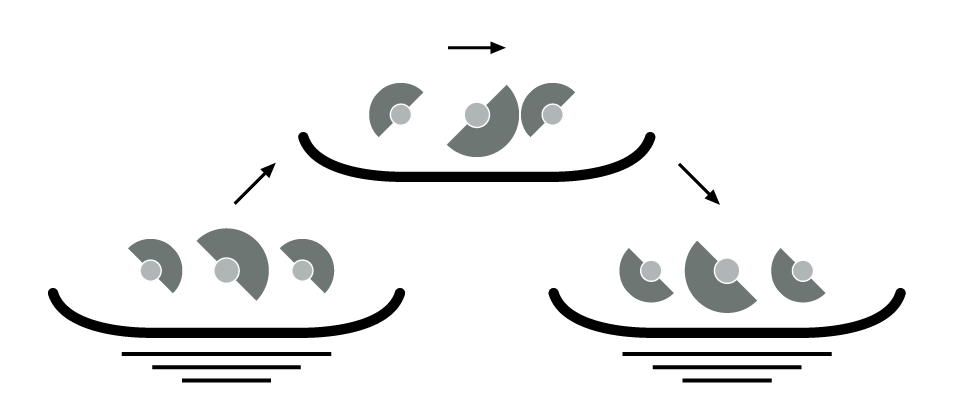

Triple-shaft technology

Industry-leading gradeability and optimal operation, even on wet and cohesive substrate.

This technologically advanced system keeps plate movement consistent, which in turn enables smooth travel – even through heavy, cohesive soils. The system also helps the machines effortlessly overcome steep grades. APH machines are impressive climbers even while backfilling saturated areas – work that can leave competitive products at a standstill.

The success of the plates starts with the use of the third shaft. With twinshaft systems, plates can rock back and forth and their leading edge can turn downward and become stuck, particularly in saturated materials.

With the Ammann exciter system, the third shaft prevents that back-and-forth movement by providing another force.

This creates more consistent drive of the plates and keeps them even, steady and above the surface – even on saturated jobsites

APH HYDROSTATIC VIBRATORY PLATES

Ammann Compaction Expert (ACE)

APH Hydrostatic Vibratory Plates can be equipped with the well known Ammann Compaction Expert (ACE), an automated compaction measurement and control system.

The benefits of ACE technology are significant:

- It can reduce the number of passes a plate compactor makes, therefore delivering savings on fuel, labour and machine wear.

- ACE helps ensure proper compaction is achieved and prevents costly rework.

- It extends the life of the compacted material – and structures placed on top of it – by providing a homogenous surface without weak spots.

APH HYDROSTATIC VIBRATORY PLATES

Customise your APH plate

No jobsite and no operator is like another. APH Plates from Ammann offer several options, allowing for customisation to make the plate fit your particular needs.

E-Start

E-Start versions fire up the plate compactor. E-Start is a convenience for experienced operators and also helps new operators get up and running effortlessly.

Extension plates

Extension plates in 2 different sizes expand the compaction surface area and add productivity. Adding an extension requires the adjustment of only 4 screws per side and can be quickly accomplished on the jobsite.

Wear-resistant base plate

A wear-resistant base plate offers extra protection when working on especially hard materials. The plate is easy to install and replace.

Rubber mat

The mats are attached to the plates and prevent cracking and breaking of paving stones and other sensitive materials while still delivering the required compaction power. Installation of the Vulcolan mats is easy and can be done directly on site.

APH HYDROSTATIC VIBRATORY PLATES

ServiceLink

Delivering the Data that Matters!

Ammann ServiceLink is a digital data management tool that provides customers with the information they want the most: machine location, battery status and operating hours. Data transfer is automatic thanks to new hardware, and access to the information is only a click away.

Manage your equipment – anytime, anywhere – with Ammann ServiceLink. This comprehensive fleet system provides key data for light compaction equipment, heavy compaction machines and asphalt pavers. You can choose which machines to track.

Highlights

- Supplies machine location, operating hours, battery status

- Provides one-click access to data

- Reliably transmits data from machines, no matter where they are

- Compatible with all machines produced by Ammann or other manufacturers

- Streamlines fleet upgrades (retrofit option)

- Easy to install

The hardware is easy to add as a retrofit

Simply attach the TCU and the battery to the machine. The TCU is activated when plugged into the battery. That’s it!