ARR 1575 TRENCH ROLLER

WHERE MANOEUVRABILITY MATTERS

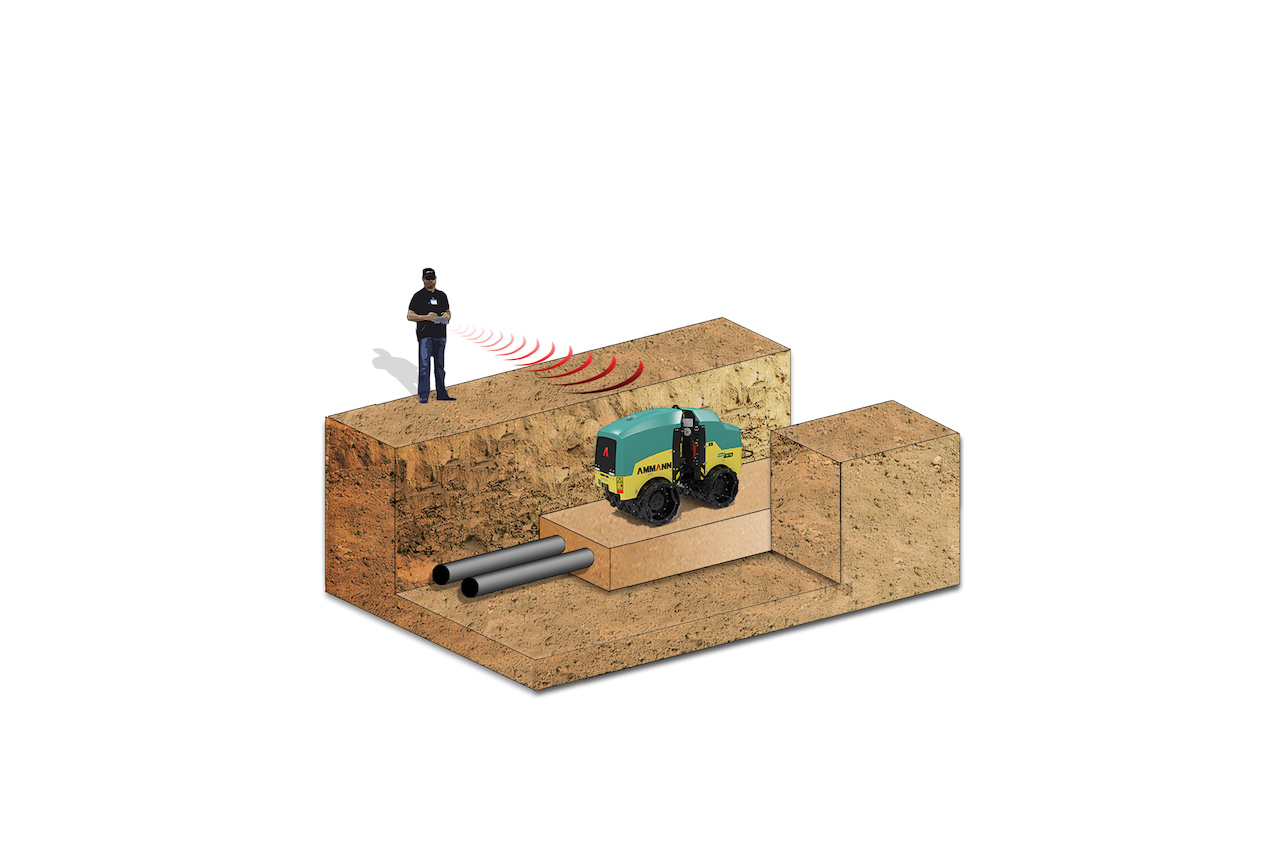

When manoeuvrability matters, contractors turn to the Ammann ARR 1575 Trench Roller. This technologically advanced machine comes in a compact body that can fit where operators can’t – or shouldn’t.

A steering joint with integrated oscillating bearing and two steering cylinders gives high steering accuracy and permanent ground contact on uneven surfaces.

The two-stage vibratory system, positioned in the centre of each drum, combines with four drive motors for exceptional machine stability and delivers the needed compaction punch. The size makes the machine a great fit in pipeline and trench applications.

Ready to learn more? Click on the product hotspots or the chat contact.

ARR 1575 TRENCH ROLLER

Infrared remote control

The infrared remote control is ergonomic, robust and waterproof. The control will not engage unless the operator has direct visibility of the machine, maximising jobsite safety.

ARR 1575 TRENCH ROLLER

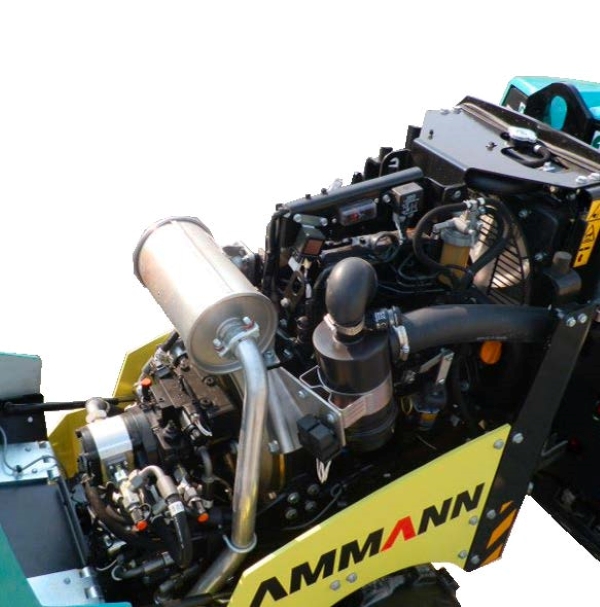

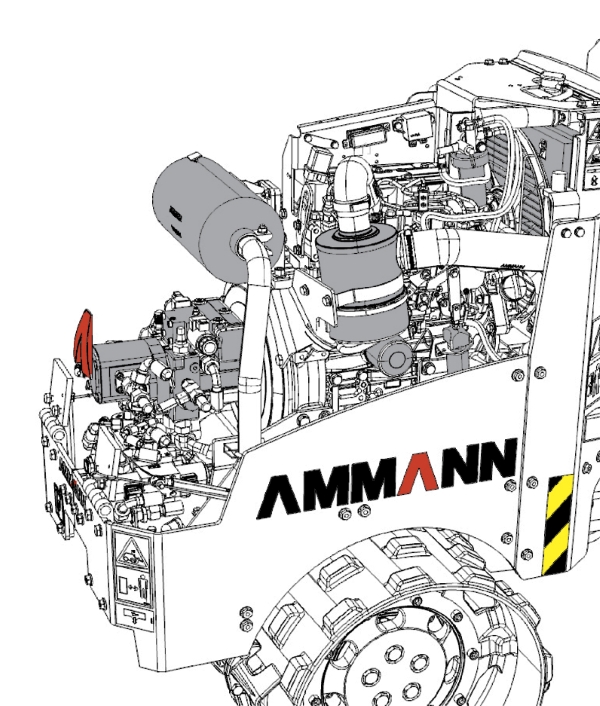

Wide-opening hood

Excellent access to all main machine components for easy serviceability.

ARR 1575 TRENCH ROLLER

ACE System

Ammann’s proprietary Intelligent Compaction system continuously measures compaction progress and communicates in real-time via LED stripes.

ELIMINATE PASSES

- Continuous compaction measurement system

- Compaction progress simply indicated via LED

- Removes guesswork from the compaction equation and avoid unnecessary passes

- Mounted on the machine

- Can measure compaction at any point on-site

ARR 1575 TRENCH ROLLER

Engine

Meets the latest emission standards.

ARR 1575 TRENCH ROLLER

Articulated joint with oscillation

The joint connects the front and rear frames and ensures balanced weight distribution and permanent ground contact.

Two steering cylinders offer great responsiveness and precision. A central steering joint with integrated oscillation features Teflon-coated bearing.

ARR 1575 TRENCH ROLLER

Four drive wheels

A powerful drive system with four independent motors offers exceptional machine traction on steep grades.

ARR 1575 TRENCH ROLLER

Drum extensions

Drum construction enables two working widths. The basic working width of 640 mm (25,2 in) can be extended to 850 mm (33.5 in), which improves productivity in wider trenches. Conversely, the working width can be narrower in tighter trenches. This innovative solution is appreciated by rental fleets, which can meet varied needs with a single machine.

ARR 1575 TRENCH ROLLER

Solar power cells

A dual charging system ensures the machine is always ready to go. The technologically advanced solar power cell can charge the remote control during the day or can be charged directly from the machine via cable connection.

ARR 1575 TRENCH ROLLER

Bolted frame

Side covers protect components to extend machine life and maximise jobsite uptime. The covers are removable because they are bolted, not welded, to the frame. This makes it much easier to access core components and hydraulic testing ports.

ARR 1575 TRENCH ROLLER

Maintenance-free parts

Heavy-duty components extend machine life and minimise the need for replacement parts. Many parts and components, including the articulation joint, drive and vibratory system, are maintenance free. This greatly reduces ownership costs by eliminating the need for replacement parts and saving time spent on machine maintenance.

ARR 1575 TRENCH ROLLER

Automatic pairing of machine control

The remote control and machine are automatically paired on a unique frequency. This innovative feature enhances safety by eliminating the risk of improper signals reaching a machine.

ARR 1575 TRENCH ROLLER

ServiceLink

Delivering the Data that Matters!

Ammann ServiceLink is a digital data management tool that provides customers with the information they want the most: machine location, battery status and operating hours. Data transfer is automatic thanks to new hardware, and access to the information is only a click away.

Manage your equipment – anytime, anywhere – with Ammann ServiceLink. This comprehensive fleet system provides key data for light compaction equipment, heavy compaction machines and asphalt pavers. You can choose which machines to track.

Highlights

- Supplies machine location, operating hours, battery status

- Provides one-click access to data

- Reliably transmits data from machines, no matter where they are

- Compatible with all machines produced by Ammann or other manufacturers

- Streamlines fleet upgrades (retrofit option)

- Easy to install

The hardware is easy to add as a retrofit

Simply attach the TCU and the battery to the machine. The TCU is activated when plugged into the battery. That’s it!