ARS 50 SOIL COMPACTOR

POWER AND FUEL EFFICIENCY

The Ammann ARS 50 Single Drum Rollers utilise advanced technology, innovative engineering and robust engines with the latest emission standards. A combination of a well-balanced engine, fully hydrostatic drive system and control deliver exceptional fuel consumption. That efficiency and a large fuel tank means a roller need only be fuelled once every three working shifts.

APPLICATIONS

- Landscaping

- Forest roads

- Municipal roads

- Walking/bicycle paths

- Pipeline construction

- Electric cable construction

ARS 50 SOIL COMPACTOR

High compaction output

Vibratory system supplies the exceptional compaction output that makes the machine an invaluable tool on the jobsite. The high output, combined with two frequency settings, ensures productivity on varied jobsites and helps reach density targets in fewer passes. Balanced machine weight (60% in the front and 40% in the rear) improves traction. The heavier front also stabilises the drum during compaction, ensuring ground contact and eliminating “jumping.”

ARS 50 SOIL COMPACTOR

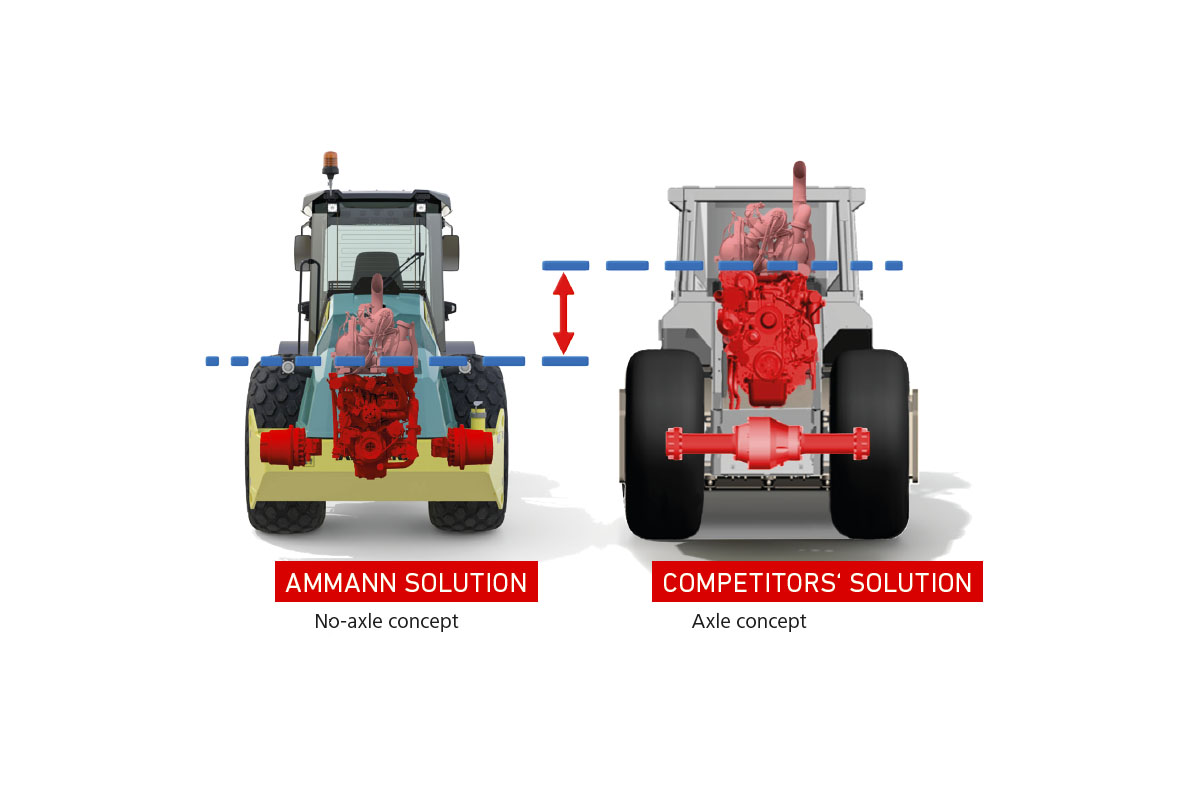

No-rear-axle concept

The innovative no-rear-axle concept separates Ammann ARS Soil Compactors from the competition. Elimination of the rear axle makes the machine more compact. The lower engine location improves the machine’s centre of gravity, which provides better stability – even on slopes. The design also improves visibility and manoeuvrability. Those factors, combined with stability, promote jobsite safety.

ARS 50 SOIL COMPACTOR

Twin-lock drive

Fully automatic traction control system that is activated without electronic controls. The system constantly adjusts the drive performance depending on actual jobsite conditions. Torque is uniformly distributed into axles to ensure ground contact and prevent slipping of the front drum and rear wheels – and to ensure the quality of the final compacted surface.

ARS 50 SOIL COMPACTOR

Articulation joint with oscillation

The central steering joint with integrated oscillation connects key components and ensures balanced machine weight distribution and consistent ground contact.

ARS 50 SOIL COMPACTOR

Simple & reliable dashboard

All control switches are easy to reach and highly visible – essential for quick operator overview. A robust dashboard is highly durable, particularly important in open-platform machines. An informational control display is located on the main machine dashboard, making it easy for operators to monitor.

ARS 50 SOIL COMPACTOR

Unobstructed visibility

Optimal visibility from the operator station maximises safety on the jobsite and during machine loading on a trailer. During operation, all objects are visible to the operator beyond a 1-by-1-meter area both in the front and back of the machine.

ARS 50 SOIL COMPACTOR

Operator workplace

A wide-opening door provides unrestricted access to the spacious, quiet cab. An easy-to-reach operator seat with an adjustable armrest optimises comfort, as does the fully vibration-isolated platform.

ARS 50 SOIL COMPACTOR

ECOdrop

Reduced fuel consumption is only the start of the savings. ECOdrop also lowers the cost of ownership through a reduction in the amount of fluids required, longer-lasting wear parts, extended service intervals and optimal access to all maintenance points. These efficiencies reduce costs and make the machines more environmentally friendly.

ARS 50 SOIL COMPACTOR

Ground servicing

The compactor is equipped with external draining points for essential fluids such as engine oil or cooling liquids. Service and maintenance points can be reached from the ground, which makes upkeep even faster.

ARS 50 SOIL COMPACTOR

Solid design

Service time is reduced in several ways. The engine compartment is easily accessible, with a robust design that protects all major components during machine operation. Hydraulic components are equipped with external test ports for quick diagnosis that maximises uptime.

ARS 50 SOIL COMPACTOR

ServiceLink

Delivering the Data that Matters!

Ammann ServiceLink is a digital data management tool that provides customers with the information they want the most: machine location, battery status and operating hours. Data transfer is automatic thanks to new hardware, and access to the information is only a click away.

Manage your equipment – anytime, anywhere – with Ammann ServiceLink. This comprehensive fleet system provides key data for light compaction equipment, heavy compaction machines and asphalt pavers. You can choose which machines to track.

Highlights

- Supplies machine location, operating hours, battery status

- Provides one-click access to data

- Reliably transmits data from machines, no matter where they are

- Compatible with all machines produced by Ammann or other manufacturers

- Streamlines fleet upgrades (retrofit option)

- Easy to install

The hardware is easy to add as a retrofit

Simply attach the TCU and the battery to the machine. The TCU is activated when plugged into the battery. That’s it!